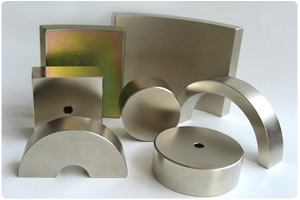

Neodymium magnets are

a type of permanent magnets also known as rare earth magnets, due to

the fact that they contain one or more of the rare earth elements of

the periodic table. Most are made of a metal alloy containing

neodymium, iron, and boron. They are much stronger than most of the

magnets people are accustomed to using, like refrigerator magnets.

Because of the forces they generate, they can be dangerous or even

cause fatal injury if not handled properly.

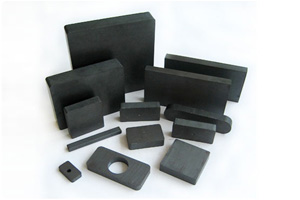

A magnet used to lift objects is a lift magnet. There are permanent magnets for this purpose and there are electromagnets used to lift things such as cars at scrap heaps.

A lifting magnet is an electromagnet designed to pick up or lift metal objects. Commonly seen in small form in school science experiments, an electromagnet is a magnet that his its magnetic properties amplified by an electrified coil. Lifting magnets vary widely in size and can be as small as a credit card or as large as a twin-sized bed. Usually, the larger lifting magnets are operated hung from a chain on a crane that is able to dangle the lifting magnet into the location necessary to retrieve the desired object. This type of magnet can be used for a wide variety of purposes, including automobile junking, construction, and demolition and cleanup.

A lift magnet is designed to pick up large or heavy objects. They range from small magnets used in recycling to pick out metal scrap to large magnets capable of lifting an automobile. You can make a small lift magnet at home using few special tools or materials.

Lifting magnets are in general introduced with secure functioning load limit capacities nearly 2000kgs, and are generally applied coupled with an electrical or manual hoist or crane, wherever the lifting magnet hooks onto the load hook.A permanent lifting magnet is often employed alongside facet a crane or hoist of some range; the magnet just hooks around the hoists load hook. Lifting magnets are used within a wide assortment of operations, whilst most often within the metal small business supposed for lifting metal plate; they are really nevertheless also often observed in ship developing yards, scrap yards, warehouses and workshops. Long lasting lifting magnets are usually obtainable in a variety of capacities, normally upto 2000kgs.

There are plenty of strengths for selecting and working with a lifting magnet; the numerous strengths are that they seriously are effortless to function and manage, provide a cost successful method to carry ferromagnetic objects, they are often put in and used by somebody human being, and they may perhaps be utilized in virtually all destinations considering the fact that lifting magnets are simple to move

It really is at this time getting expanded on at a continuous cost, getting refined and optimized if you want that any regarded among us casual doityourselfers can generate and start making our very own personal electric power in very small quite a bit a lot more than the usual weekend, in addition to a little bit over 100 in cloth expenditures. Take into account it or not, all these parts are available out of your native setting up give, hardware, and vehicle locations retain.

Edit by http://www.senmagnetics.com

A magnet used to lift objects is a lift magnet. There are permanent magnets for this purpose and there are electromagnets used to lift things such as cars at scrap heaps.

A lifting magnet is an electromagnet designed to pick up or lift metal objects. Commonly seen in small form in school science experiments, an electromagnet is a magnet that his its magnetic properties amplified by an electrified coil. Lifting magnets vary widely in size and can be as small as a credit card or as large as a twin-sized bed. Usually, the larger lifting magnets are operated hung from a chain on a crane that is able to dangle the lifting magnet into the location necessary to retrieve the desired object. This type of magnet can be used for a wide variety of purposes, including automobile junking, construction, and demolition and cleanup.

A lift magnet is designed to pick up large or heavy objects. They range from small magnets used in recycling to pick out metal scrap to large magnets capable of lifting an automobile. You can make a small lift magnet at home using few special tools or materials.

Lifting magnets are in general introduced with secure functioning load limit capacities nearly 2000kgs, and are generally applied coupled with an electrical or manual hoist or crane, wherever the lifting magnet hooks onto the load hook.A permanent lifting magnet is often employed alongside facet a crane or hoist of some range; the magnet just hooks around the hoists load hook. Lifting magnets are used within a wide assortment of operations, whilst most often within the metal small business supposed for lifting metal plate; they are really nevertheless also often observed in ship developing yards, scrap yards, warehouses and workshops. Long lasting lifting magnets are usually obtainable in a variety of capacities, normally upto 2000kgs.

There are plenty of strengths for selecting and working with a lifting magnet; the numerous strengths are that they seriously are effortless to function and manage, provide a cost successful method to carry ferromagnetic objects, they are often put in and used by somebody human being, and they may perhaps be utilized in virtually all destinations considering the fact that lifting magnets are simple to move

It really is at this time getting expanded on at a continuous cost, getting refined and optimized if you want that any regarded among us casual doityourselfers can generate and start making our very own personal electric power in very small quite a bit a lot more than the usual weekend, in addition to a little bit over 100 in cloth expenditures. Take into account it or not, all these parts are available out of your native setting up give, hardware, and vehicle locations retain.

Edit by http://www.senmagnetics.com